The Synthesis And Applications Of Carbon Nanofibers

How is Carbon Nanofibers Synthesized?

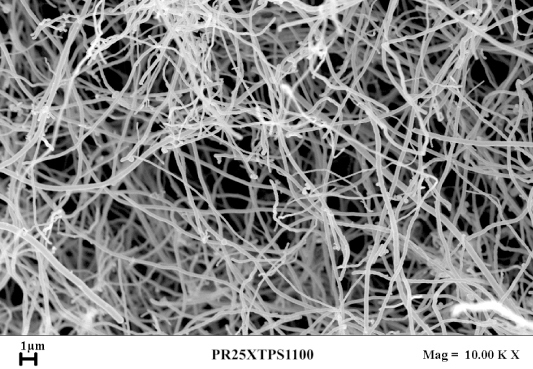

CCVD or Catalytic Chemical Vapor Deposition is a popular method utilized for the synthesis of carbon nanofiber. In this technique, the gas phase molecules of the system are decomposed in high temperature and carbon gets deposited on substrate by the action of transition metal catalyst that leads to the growth of fiber around the catalyzed particles.

Put it simply, there are different stages involved in the entire process of synthesis which are carbon deposition, gas decomposition, growth of fiber, fiber thickening, purification and final results. The diameters of nanofibers are based on the size of catalyst. Further, this process has been categorized into two types and they are floating catalyst process and fixed catalyst process.

In floating or continuous catalyst process, sub-micrometer lengths and diameters of carbon nanofiber is channeled using organometallic compounds. The compounds are apparently mixed with benzene, that would produce ultra-fine particles of catalyst and the same would initiate fine nanofibers.

On the other hand for fixed a mixture of helium, hydrogen or hydrocarbon is passed on mullite along with catalyst made up of fine iron particles with a temperature maintained to 1000 degrees Celsius. The growth of fibers can be seen in as less as 10 minutes, when the gas reduces.

Put it simply, there are different stages involved in the entire process of synthesis which are carbon deposition, gas decomposition, growth of fiber, fiber thickening, purification and final results. The diameters of nanofibers are based on the size of catalyst. Further, this process has been categorized into two types and they are floating catalyst process and fixed catalyst process.

In floating or continuous catalyst process, sub-micrometer lengths and diameters of carbon nanofiber is channeled using organometallic compounds. The compounds are apparently mixed with benzene, that would produce ultra-fine particles of catalyst and the same would initiate fine nanofibers.

On the other hand for fixed a mixture of helium, hydrogen or hydrocarbon is passed on mullite along with catalyst made up of fine iron particles with a temperature maintained to 1000 degrees Celsius. The growth of fibers can be seen in as less as 10 minutes, when the gas reduces.

What Are The Applications of High Quality Carbon Nanofibers?

The spectacular properties of high quality carbon nanofibers have made them suitable for not just one but endless applications including field electron emissions, scanning probe microscopy files, composite materials, electrode materials, oil spill remediation, gene delivery and many more.